Cleanzine: your weekly cleaning and hygiene industry newsletter 18th April 2024 Issue no. 1110

Cleanzine: your weekly cleaning and hygiene industry newsletter 18th April 2024 Issue no. 1110

Your industry news - first

The original and best - for over 20 years!

We strongly recommend viewing Cleanzine full size in your web browser. Click our masthead above to visit our website version.

CSSA's Innovation & Technology Executive Bulletin examines battery technology

The Cleaning & Support Services Association has issued an Innovation & Technology Executive Bulletin, which looks at battery technology in detail, examining the different types and their advantages and disadvantages and in particular with regard to their use in cleaning equipment. It was compiled using information supplied BSA (Battery Safety Hub) and ICE - (Industrial Cleaning Equipment).

The Cleaning & Support Services Association has issued an Innovation & Technology Executive Bulletin, which looks at battery technology in detail, examining the different types and their advantages and disadvantages and in particular with regard to their use in cleaning equipment. It was compiled using information supplied BSA (Battery Safety Hub) and ICE - (Industrial Cleaning Equipment).

Since the inception of batteries, Lead Acid has been the main chemical coupling for motive power\cleaning machine applications. In the early 80s, this became available in a sealed form and in either AGM or Gel versions.

AGM technology became popular in the early 1980s as a sealed lead acid battery for military aircraft, vehicles and UPS to reduce weight and improve reliability. The sulphuric acid is absorbed by a very fine fibreglass mat, making the battery spill-proof.

A modern gel battery is a battery with a gelified electrolyte; the sulphuric acid is mixed with fumed silica, which makes the resulting mass gel-like and immobile. With gel electrolyte the separator is no longer such a critical, hard-to-make component, and cycle life is increased, in some cases dramatically. Shedding of active material from the plates is reduced.

The underlying problem with all lead acid batteries is the requirement for an excessively long recharge time arising from a two-stage process: bulk charge and float charge. All lead acid batteries; irrespective of whether being VRLA Flooded, Gel, AGM and Flooded Tubular are quick to charge to 70% of capacity within two or three hours, but this technology requires another nine to 10 hours to 'float charge' after the initial charge.

The underlying problem with all lead acid batteries is the requirement for an excessively long recharge time arising from a two-stage process: bulk charge and float charge. All lead acid batteries; irrespective of whether being VRLA Flooded, Gel, AGM and Flooded Tubular are quick to charge to 70% of capacity within two or three hours, but this technology requires another nine to 10 hours to 'float charge' after the initial charge.

The charging of the existing technologies mentioned above is a major challenge across many industries; least of all the cleaning market. Lead acid is not designed to be 'opportunity' charged as this will shorten the life of the battery and its capacity. Some chargers are now coming with a data logging capability which records some 32 - 60 charging cycles; this assists in the diagnosis of why a battery may not be functioning as it ?should... this could, for example, be down to interrupted power supply or the operator not allowing the battery to fully recover.

Lithium-ion is being looked upon as the future for a number of applications including renewable energy and motive power for use in cleaning machines. It is the power behind the hybrid car and the full electric vehicle and is now available in Lithium Phosphate (LiFePO4). These cells experience a slower rate of capacity loss (aka greater cycle-life).

One important advantage over other lithium-ion chemistries is thermal and chemical stability, which improves battery safety. We have seen the Boeing 787 fires and heard of instances of laptops/mobile phones catching fire. LiFePO4 is an intrinsically safer cathode material than LiCoO2 and manganese spinel and is now only used as coupling for industrial applications.

The benefits of Lithium vs. Lead Acid:

* Zero maintenance

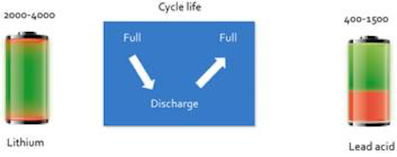

* Double/quadruple the cycle life of lead acid batteries (dependent on type)

* 'Opportunity' charge-safe

* Fast charge - on average, two hours or less

* Higher efficiency which means more usable power at the drive wheel for longer

* Spare batteries not required?

* Less space required for battery

* 'Plug and play' approach with one battery pack

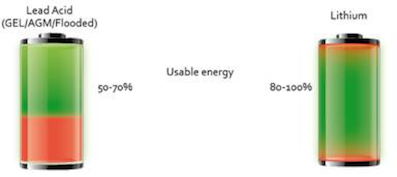

* 100% of capacity can be used

Downside vs. Lead Acid:

* Lead acid is stable Lithium is still in early development

* Lithium needs constant monitoring and communication with the equipment via complex communication to ensure it is not over-charged nor discharged

* Unlike lead acid, individual Lithium blocs have to have their own BMS (battery monitoring system) this can be difficult to ensure batteries are balanced

* Cost of disposal

The costs vs. Lead Acid:

Straightforward cost comparison should not be just amp/hr for amp/hr (generally around three - four times the cost) However, the actual energy extracted can be 30% more per discharge (giving either longer run times, or if not required, smaller capacity Lithium can be considered)

Typical Example:

Lead Acid 12v 100 amp/hr Gel Battery approx. £175.00

Lithium 12.6v 100 amp/hr Battery approx. £500.00

Cycle Life Gel - 700 cycles = cost per cycle £0.25 (not including charging)

Lithium - 3000 + cycles = cost per cycle £0.16 (not including charging)?

Clearly Gel, AGM or flooded batteries will be around for many years to come but due to their cycle life and lack of sophisticated control, will need to be replaced more often than a Lithium alternative.

It is worth also bearing in mind that the replacement entails time, installation and transportation costs, which further negates the higher initial capital cost of Lithium as does the lower cost of recharging Lithium - two hours versus 12 hours.

Flexibility is a major area where Lithium has an advantage over conventional battery technology. In a market where the cost of labour is increasing, the ability to be able to use equipment longer both with and without an operator, along with the benefit of faster recharge times, will drive the demand for Lithium options to be made available.

Many of the car manufacturers now are looking to sell on the Lithium cells for use in both RE applications and motive power, given that they have an afterlife, so perhaps this will assist in the technology becoming a more commercial solution, faster?

BSH (Battery Safety Hub) is working with Industrial Cleaning Equipment (ICE) looking at ways in which power can be rented due to the extended lifetime Lithium can offer, and in what environment Lithium would deliver the best benefit to the end user or contractor.

If you'd like to know more about the benefits of joining a reputable industry association such as the CSSA, contact John Findlater via:

21st July 2016